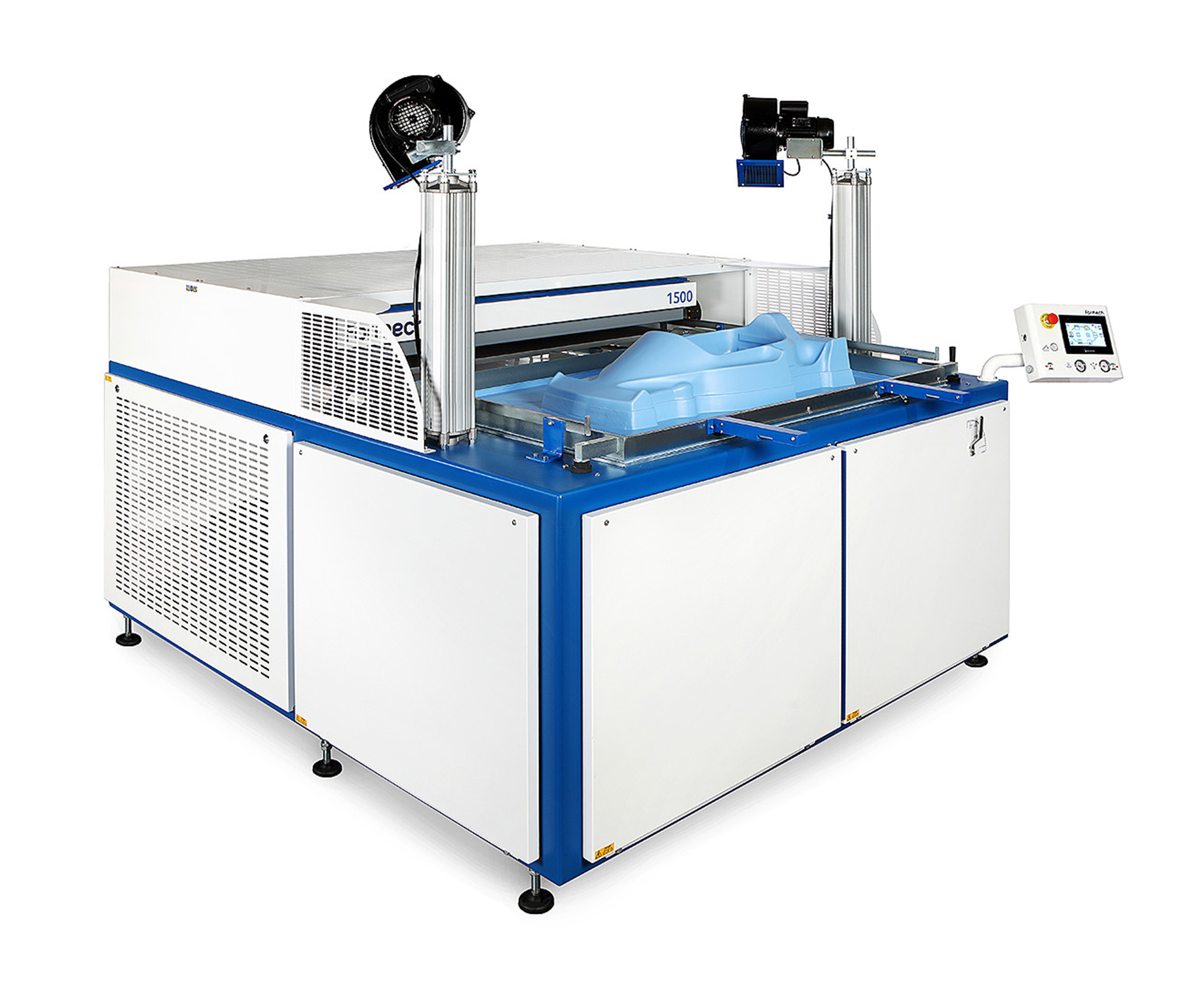

Large format

Download spec sheet

Download spec sheet

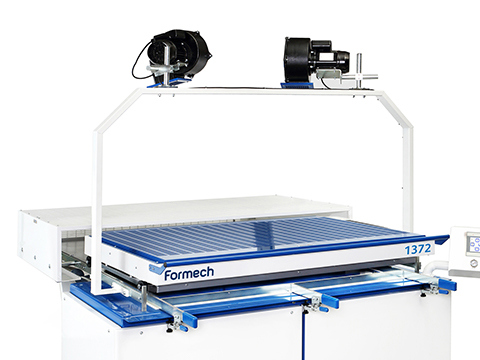

Formech 1372 vacuum former

Featuring the intuitive 'Formech Cycle View' user interface and pneumatic clamping, Formech 1372 offers an upgrade from the manual machines. Combining a greater forming area with semi-automatic capabilities, this model is the perfect choice for film and theatre, universities, automotive and aerospace R&D departments. Click here to watch the large format models in action

Compare

1372 Technical specifications

mm

in

Forming capacity

| Forming area | 1330 x 620 mm |

| Sheet size | 1372 x 660 mm |

| Max depth of draw | 420 mm |

| Max material thickness | 6 mm |

Dimensions

| Machine width | 2144 mm |

| Machine height | 1320 mm |

| Machine depth | 2099 mm |

| Machine weight | 600 kg |

Power

| Power consumption (kW) | 17 |

| 3 Phase power requirements | 380-415V / 40A |

Air

| Air requirements (PSI/bar) | 87 / 6 |

| Operating interface | 7" Colour HMI |

| Vacuum pump type | Dry rotary vane pump |

| Pump flow (SCFM @ 0 in. / 60Hz) | 18 |

| Pump flow m3 /h @ 0mbar / 50Hz | 25 |

| Mould release method | External air supply |

Heating

| Heater type | Quartz |

| Heating zones | 15 |

Large-format-semi-automatic Formech machine features and specifications are subject to change without notice as part of our continual product development program

More from this range: Large format

Related Products