Large format

Download spec sheet

Download spec sheet

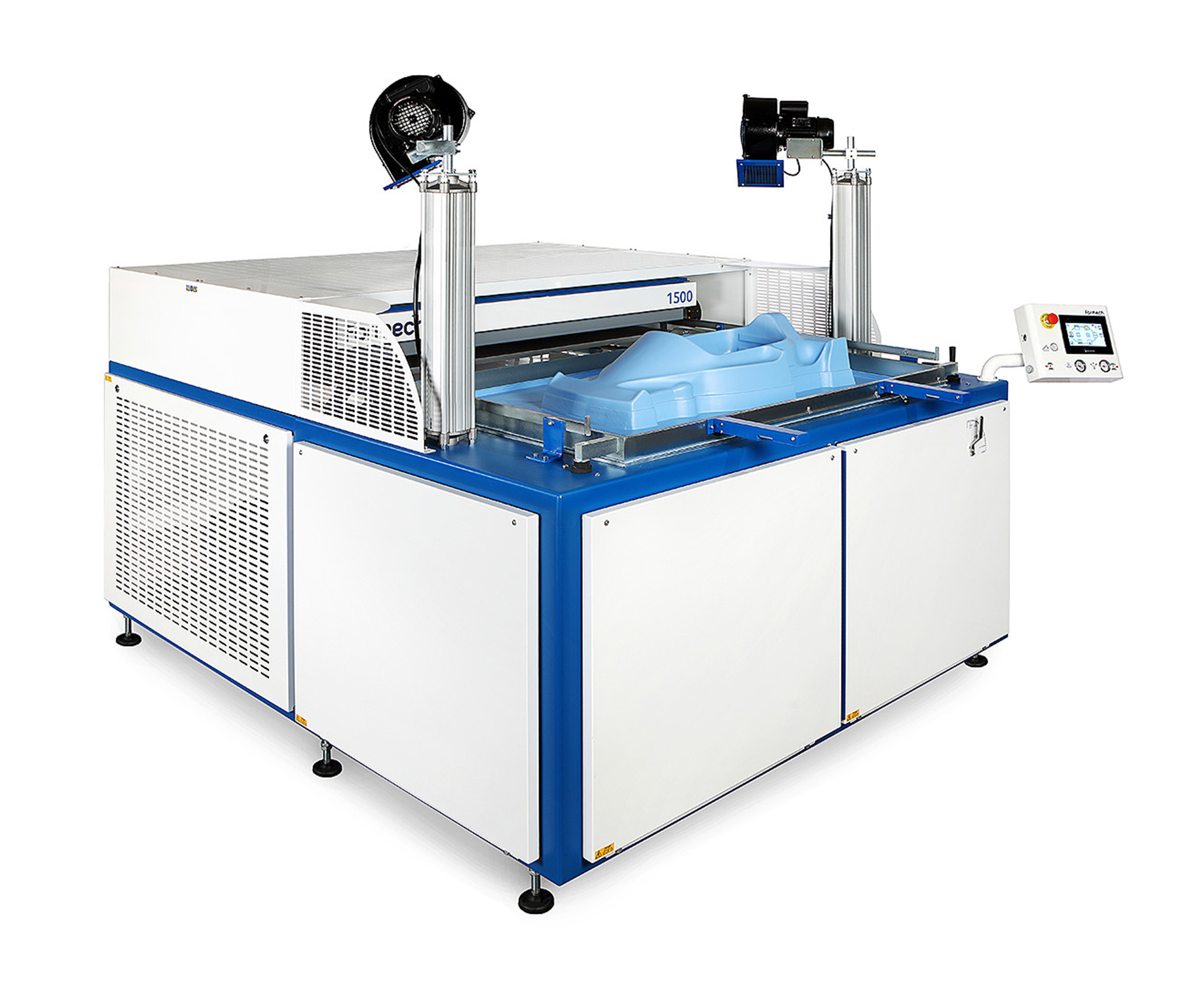

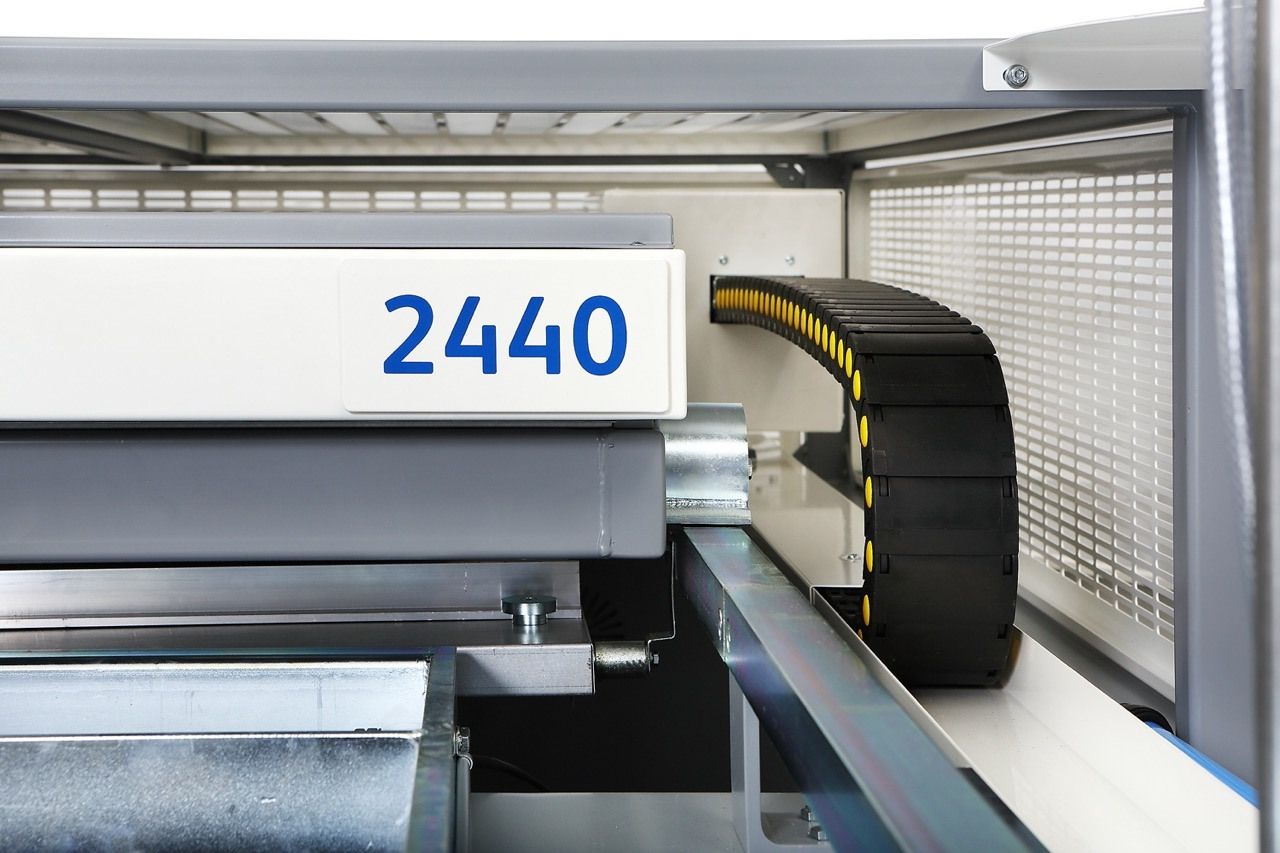

Formech 2440 vacuum former

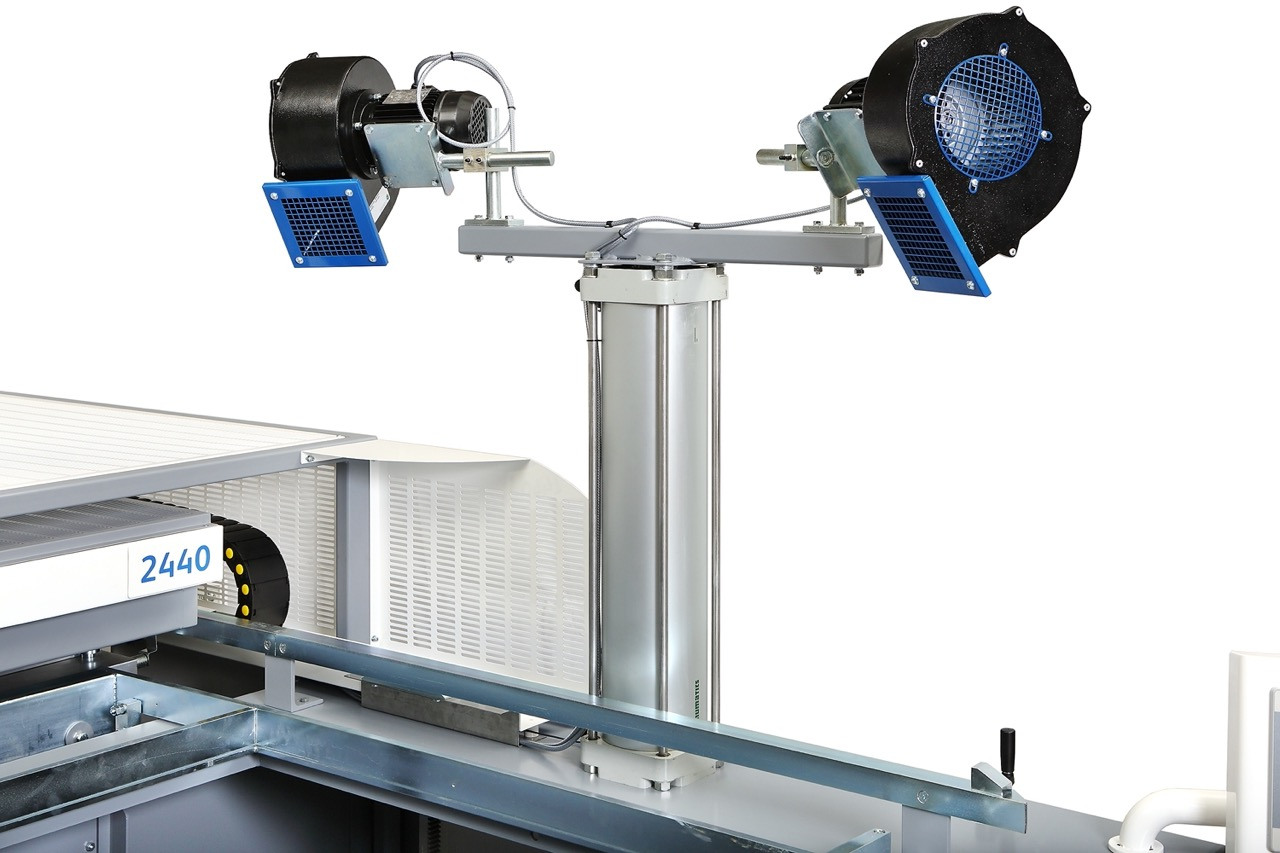

Formech 2440 represents a breakthrough in easy-to-use large format vacuum forming machines. With 48 heating zones, four cooling fans, two vacuum tanks, and a substantial increase in the forming area, this machine is the pinnacle of the semi-automatic range. Click here to watch the large format models in action

Compare

2440 Technical specifications

mm

in

Forming capacity

| Forming area | 2380 x 1160 mm |

| Sheet size | 2440 x 1220 mm |

| Max depth of draw | 600 mm |

| Max material thickness | 6 mm |

Dimensions

| Machine width | 3762 mm |

| Machine height | 2200 mm |

| Machine depth | 3952 mm |

| Machine weight | 1800 kg |

Power

| Power consumption (kW) | 52 |

| 3 Phase power requirements | 380-415V / 50Hz / 80A |

Air

| Air requirements (PSI/bar) | 87 / 6 |

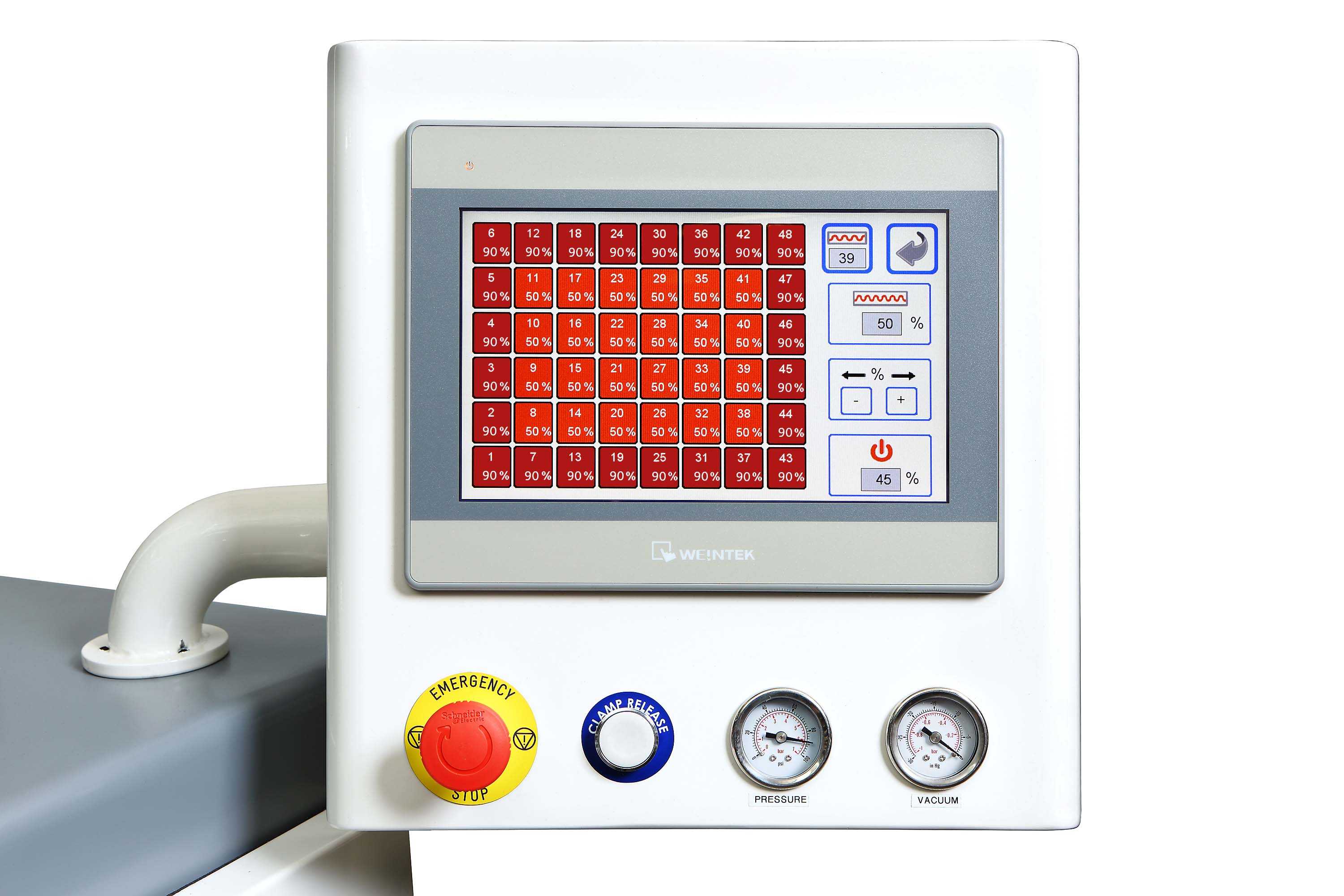

| Operating interface | 10" Colour HMI |

| Vacuum pump type | Oil rotary vane pump |

| Pump flow (SCFM @ 0 in. / 60Hz) | 49.4 |

| Pump flow m3 /h @ 0mbar / 50Hz | 70 |

| Mould release method | External air supply |

Heating

| Heater type | Quartz |

| Heating zones | 48 |

Large-format-semi-automatic Formech machine features and specifications are subject to change without notice as part of our continual product development program

More from this range: Large format

Related Products